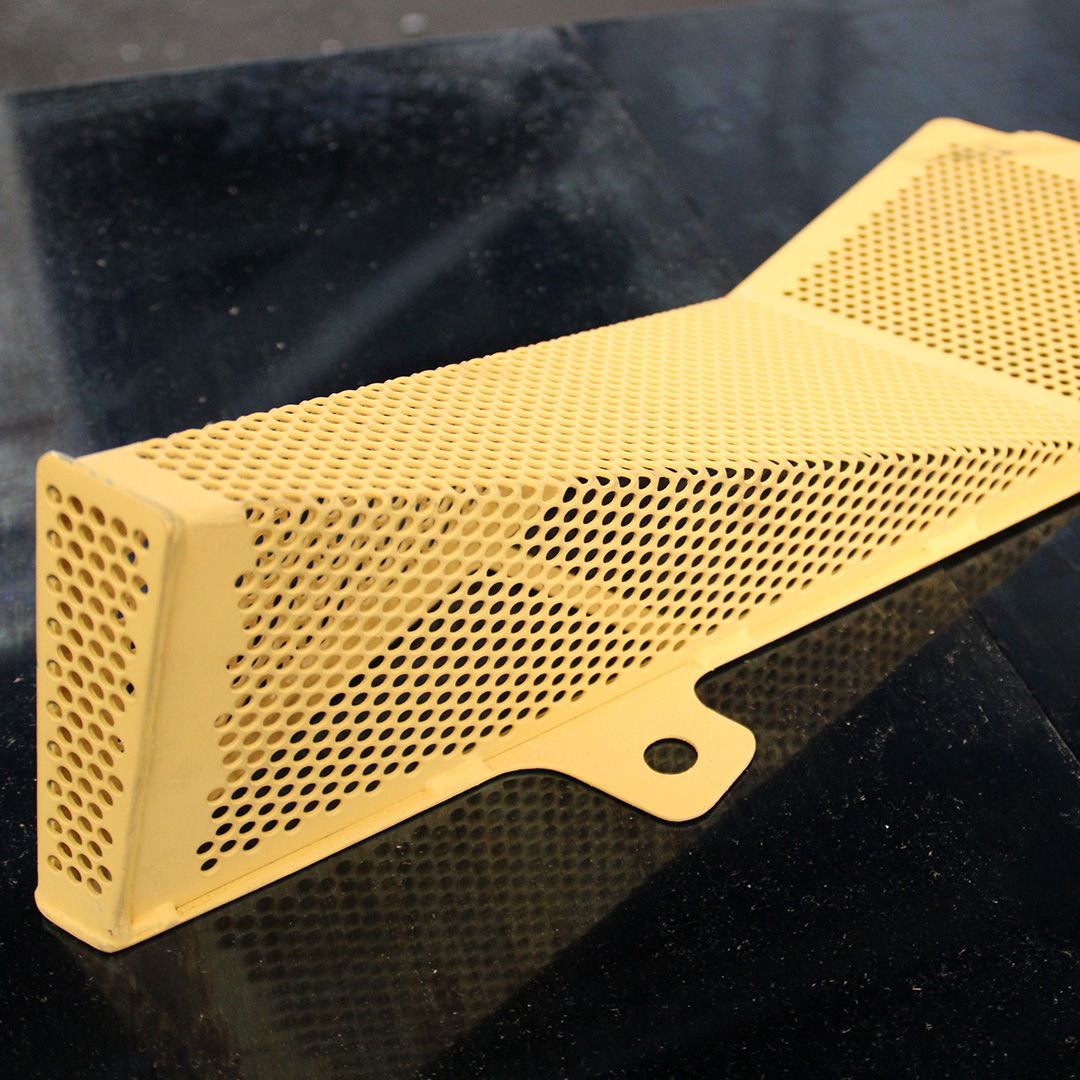

NEW LASER CUTTER

Increased Cutting Capacities and Speeds

We have a new TCI fiber optic laser that increases our cutting capacities up to 1” thick on carbon steel, stainless steel, and aluminum. Thickness limits on other materials have improved as well.

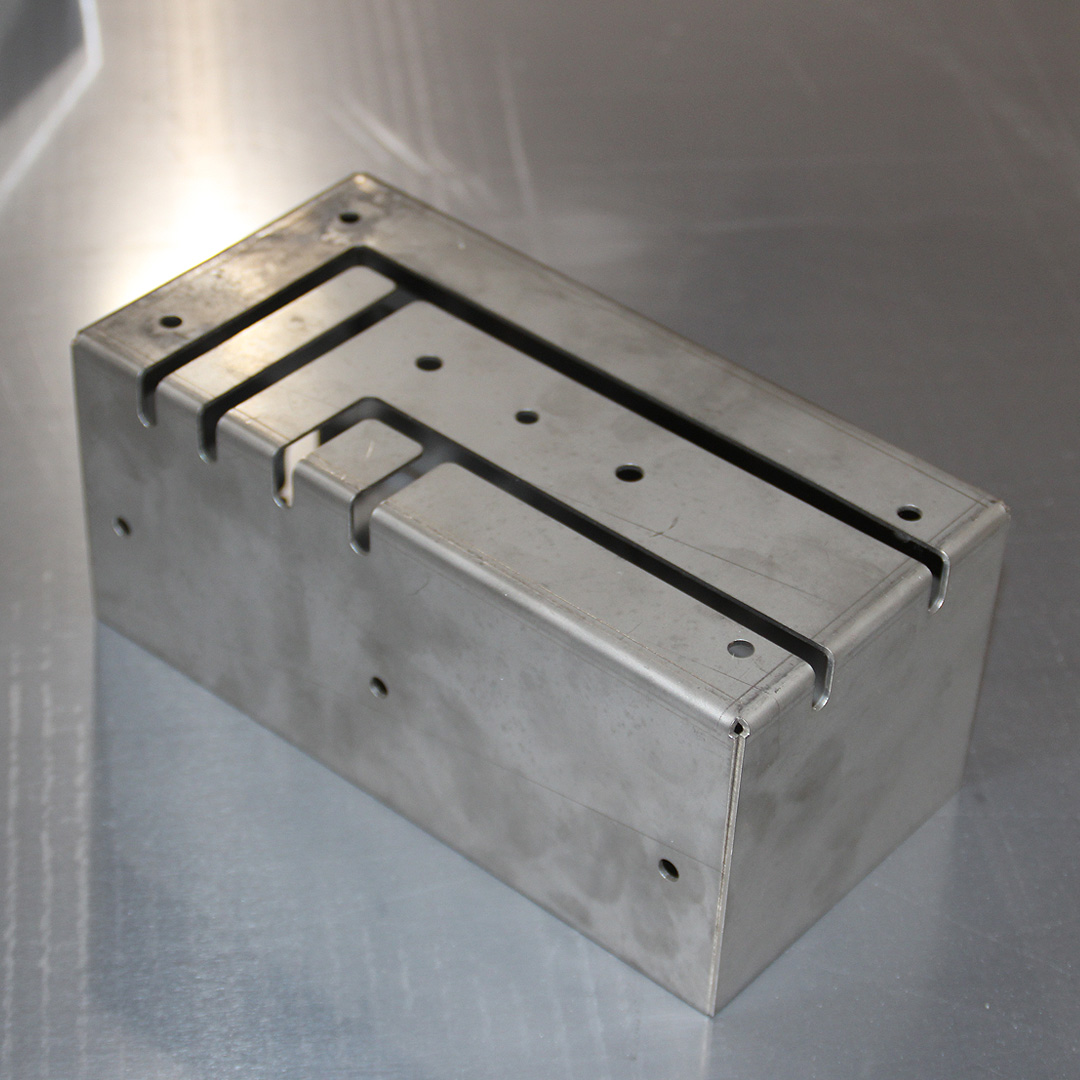

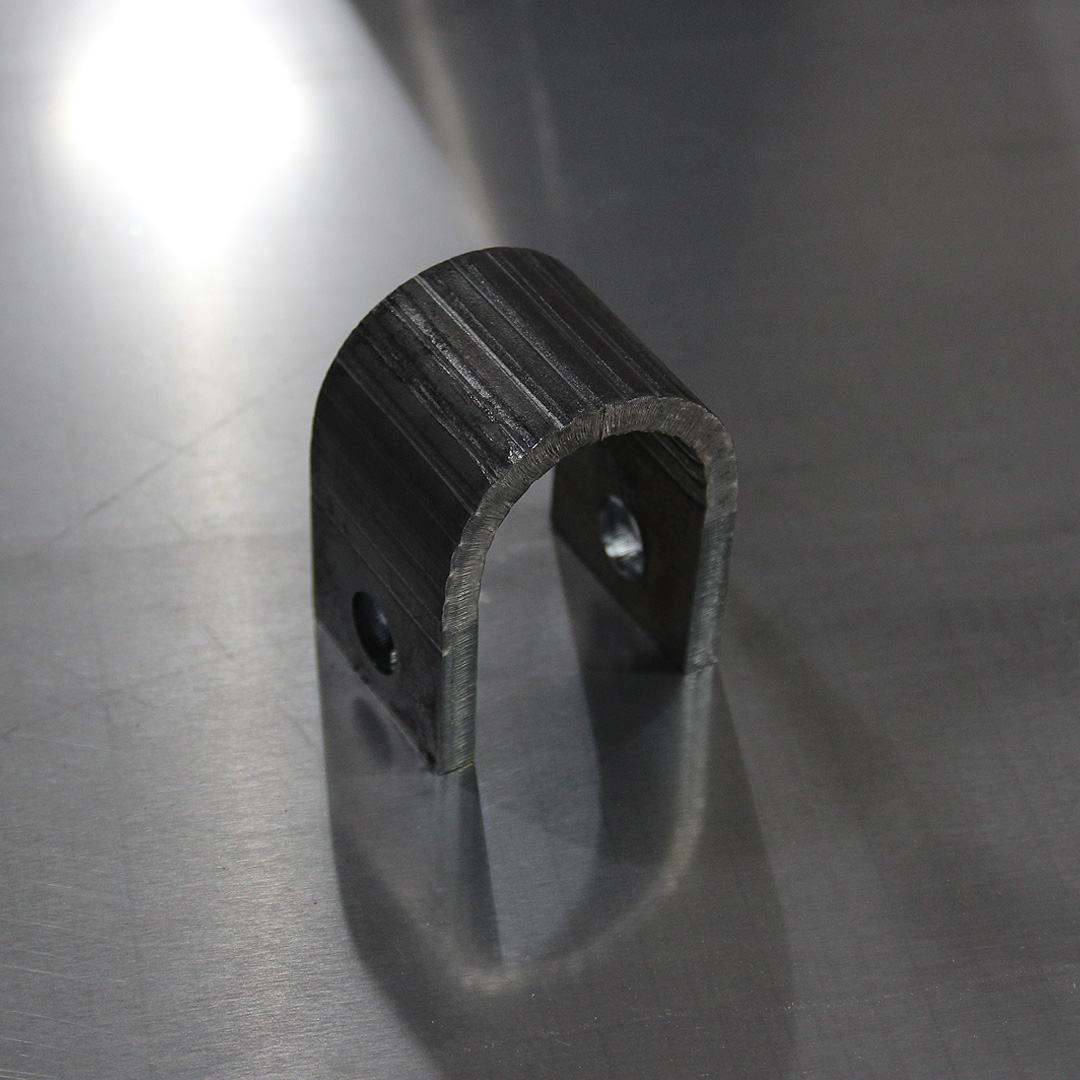

BUILT FOR SUCCESS

CUSTOM PARTS MADE FAST

We make it our business to get our customers get back to their business as quickly as possible!

ABOUT ALLOWAY

Established 1942

Alloway Stamping is a company with experience in several areas of job shop production.